Magnetic drive pumps (MDP) are primarily used for transporting corrosive chemicals. Unlike conventional centrifugal pumps (which often leak due to mechanical seal failure), magnetic pumps rely on magnetic force to drive fluid flow. They require no seals, eliminate leakage, and demand minimal maintenance. This article provides a detailed overview of magnetic drive pumps, including their operating principles, core components, and maintenance considerations. Please continue reading.

A Magnetic Drive Pump (MDP) is a classic example of a seal-less pump. In traditional centrifugal pumps, the connection between the motor and pump body relies on rubber or carbon seals to prevent leakage. However, these seals wear out very quickly in high-frequency industrial operating environments, typically requiring replacement within less than three months. Magnetic drive pumps replace traditional sealing structures with magnetic coupling transmission devices, enabling non-contact connection between the motor and impeller. This effectively eliminates leakage risks, significantly enhancing pump reliability and service life.

Magnetic drive pumps operate by using an electric motor to rotate an outer magnetic rotor. The magnetic field penetrates an isolation sleeve, driving the inner magnetic rotor and impeller to rotate synchronously, achieving non-contact power transmission. This design replaces the traditional dynamic seal prone to leakage with a static seal, enabling zero-leakage operation. Most magnetic pumps employ synchronous magnetic drive, where inner and outer magnets rotate in unison via magnetic force. In asynchronous magnetic drive (torque ring type), the inner magnet is replaced by a torque ring that rotates at a slightly lower speed under the external magnetic field, enabling operation under higher temperature conditions. The working principle involves the following steps:

(1) Permanent magnets generate a magnetic field that attracts and fixes the impeller in position through magnetic force;

(2) The motor drives the pump shaft to rotate, thereby turning the impeller;

(3) The impeller's rotation creates negative pressure inside the pump casing, drawing in liquid;

(4) The liquid is expelled by the impeller's centrifugal force, completing the pumping process.

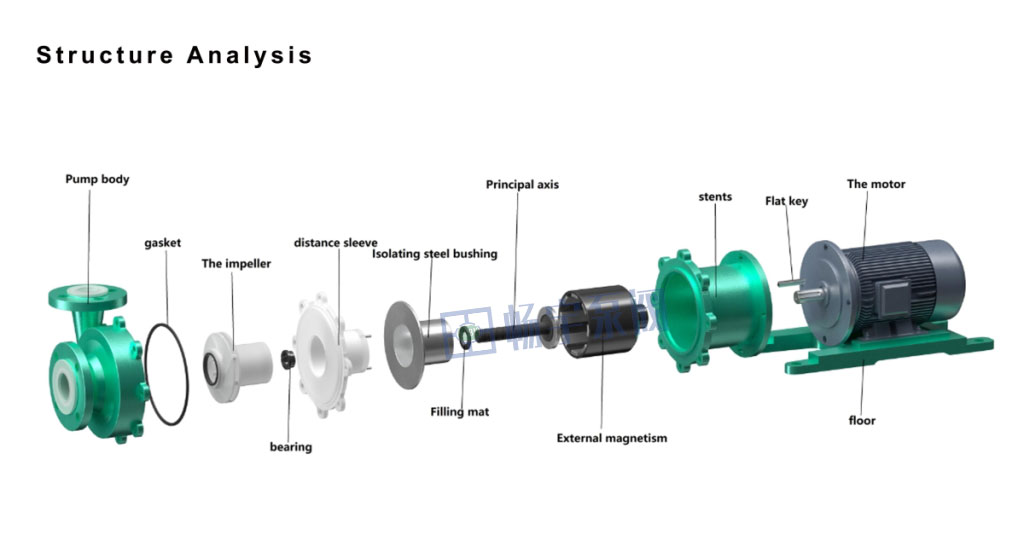

Magnetic drive pumps primarily consist of the following components:

Pump Housing: Supports and conveys liquids while creating the required pressure environment;

Impeller: Pressurizes and conveys liquids during rotation;

Motor: Serves as the power source, driving the external magnetic rotor;

Permanent Magnets: Generate a stable magnetic field, transmitting power via magnetic coupling to achieve non-contact drive.

Chemical Industry: Suitable for conveying highly corrosive media such as sulfuric acid, hydrochloric acid, and sodium hydroxide, ensuring zero leakage and extended equipment lifespan.

Pharmaceutical Industry: Enables precise and stable liquid transfer in drug manufacturing, particularly suited for high-purity and contamination-free requirements.

Petroleum Industry: Used for conveying and circulating crude oil, petrochemical solvents, and drilling fluids, reducing leakage risks and equipment wear.

Environmental Protection: Widely applied in treating and transporting sewage, waste liquids, and hazardous chemical effluents, offering safety and reliability.

Electroplating & Semiconductor: Suitable for conveying highly corrosive special chemical media like electroplating solutions and etching solutions, ensuring stable production line operation.

Magnetic drive pumps offer key advantages including leak-free operation, low maintenance, and high reliability. They are particularly suited for conveying corrosive, toxic, or volatile liquids, finding extensive use in demanding industries such as chemical processing, pharmaceuticals, and environmental protection. However, they also have limitations, such as slightly lower efficiency, sensitivity to media and temperature, high requirements for installation precision and isolation sleeve material. Additional auxiliary measures and cost investments are needed when conveying media containing solid particles or high-temperature media. Below are the advantages and disadvantages of magnetic drive pumps:

Leak-Free Design: Utilizes magnetic coupling transmission, eliminating mechanical shaft seals and completely removing the risk of liquid leakage.

Overload Protection: Inherent overload protection ensures safer and more reliable operation.

Low Maintenance: Simplified structure minimizes seal replacement frequency and reduces maintenance workload.

Wide Applicability: Moderate manufacturing complexity (excluding stringent magnetic circuit and material requirements) makes it suitable for large-scale industrial applications.

Efficiency Limitation: Slightly lower efficiency than conventional centrifugal pumps; prohibited from dry running or operating below 30% of rated flow.

Medium Restriction: Unsuitable for media containing solid particles or magnetic impurities to prevent wear and blockage.

Temperature Sensitivity: Limited by permanent magnet and isolation sleeve materials; prolonged high temperatures may cause demagnetization or damage.

Complex Requirements: Demands high installation precision, cooling systems, and specialized isolation sleeve materials, increasing cost and technical complexity.

The primary distinction between magnetic drive pumps and conventional centrifugal pumps lies in their sealing mechanisms. Magnetic drive pumps utilize magnetic coupling for leak-free transmission, whereas centrifugal pumps rely on mechanical seals or packing seals, which carry inherent leakage risks.

| Comparison Items | Magnetic Drive Pump | Traditional Centrifugal Pump |

| Sealing Method | Static seal + magnetic coupling, leak-free | Dynamic mechanical seal or packing seal, prone to wear and leakage |

| Maintenance Cost | Low pressure, no seal replacement required | High leakage rate, requiring regular seal replacement |

| Applicable Media | Highly corrosive, toxic, hazardous, and volatile liquids | Suitable for ordinary water, mildly corrosive or non-hazardous media |

| Operational Safety | High pressure, to avoid leakage and environmental risks | Relatively low reliability, potential safety hazards due to leakage |

| Structural Complexity | Slightly higher pressure, requires isolation sleeve and magnetic coupling device | Simple design with direct shaft drive |

| Applicable Operating Conditions | High pressure, suitable for high-demand industries such as chemicals, pharmaceuticals, environmental protection, and semiconductors | Common applications include industrial water supply, circulation, and drainage systems |

In summary, magnetic drive pumps are a leak-free pump type that utilizes magnetic coupling transmission to achieve power output. With their safety, reliability, and low maintenance characteristics, they are widely used in industries with extremely high requirements for medium transportation, such as chemical, pharmaceutical, environmental protection, and petroleum. Although they have certain limitations in efficiency, temperature adaptability, and fluid restrictions, magnetic drive pumps remain an ideal choice for handling corrosive, toxic, or high-value fluids when properly selected and applied.

Should you have any questions regarding magnetic drive pump selection, application, or technical specifications, please feel free to contact our professional team at any time. We will provide you with one-on-one solutions and technical support.

ساعات العمل لدينا

الإثنين 21/11 - الأربعاء 23/11: 9 صباحًا - 8 مساءً

الخميس 24/11: مغلق - عيد شكر سعيد!

الجمعة 25/11: 8 صباحًا - 10 مساءً

السبت 26/11 - الأحد 27/11: 10 صباحًا - 9 مساءً

(جميع الساعات بالتوقيت الشرقي)