Aug 30, 2025

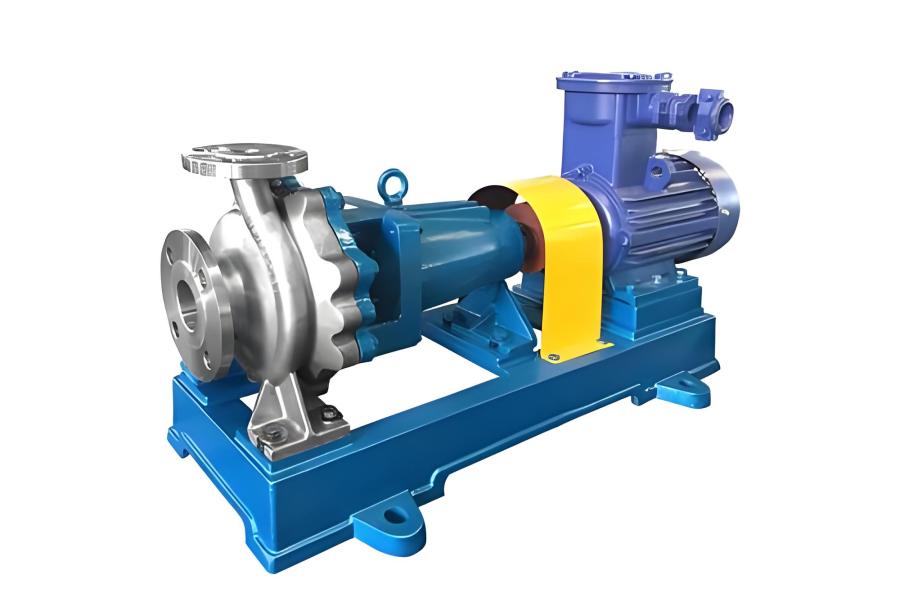

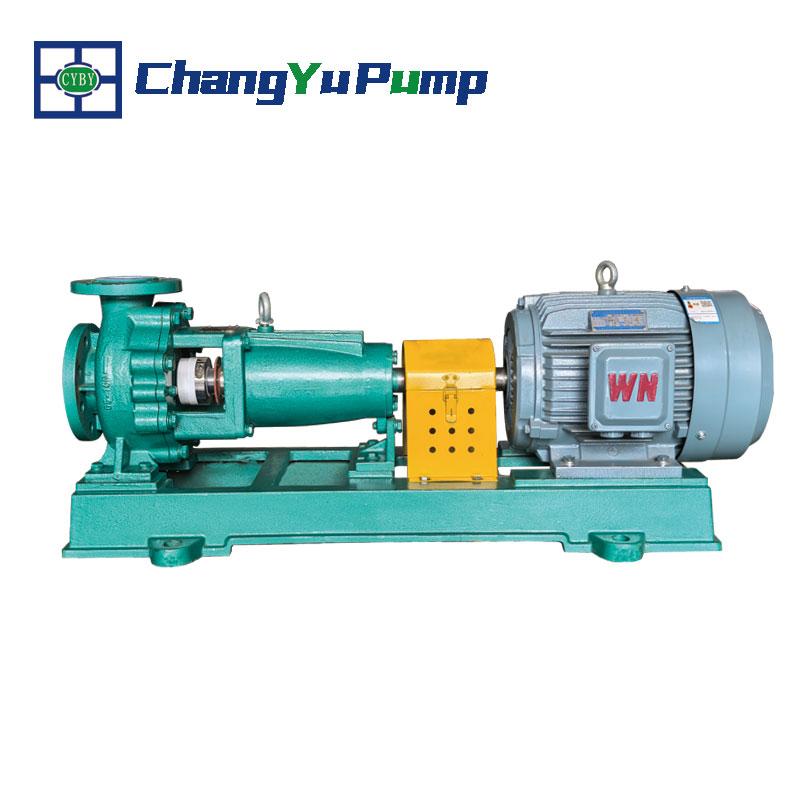

Centrifugal pumps are fluid transfer equipment widely used in industrial, agricultural, and municipal applications. Their primary function is to generate centrifugal force through a rotating impeller, transferring liquids from low-pressure areas to high-pressure zones to achieve lifting, circulation, or pressurization. So, what types of centrifugal pumps exist? What are the characteristics and suitable scenarios for different structures? This article provides a detailed analysis of the seven primary classification methods for centrifugal pumps, helping you gain a comprehensive understanding of their types and key selection criteria.

I. Classification by Working Pressure

Based on operating pressure, centrifugal pumps are categorized into low-pressure, medium-pressure, and high-pressure pumps.

Low-pressure pumps are suitable for scenarios requiring pressures below 100 meters water column (mwc), such as general water supply systems.

Medium-pressure pumps operate at pressures between 100 and 650 mwc and are commonly used in industrial processes.

High-pressure pumps handle pressures exceeding 650 mwc, making them ideal for high-pressure spraying, boiler feedwater, and similar applications.

II. Classification by Number of Impellers

Based on the number of impellers, pumps can be categorized as single-stage or multi-stage.

Single-stage pumps feature a single impeller, offering simple structure and easy maintenance;

Multi-stage pumps mount multiple impellers on a single shaft, with total head being the sum of individual stage heads. They are suitable for high-head applications like high-rise water supply or mine drainage.

III. Classification by Impeller Inlet Configuration

Pumps are categorized as single-suction or double-suction based on inlet arrangement.

Single-suction pumps feature impellers with inlet on one side only, offering compact design;

Double-suction pumps have impellers with inlet on both sides, delivering higher flow rates and smoother operation. They are suitable for high-volume applications like municipal water supply or large-scale irrigation.

IV. Classification by Pump Shaft Orientation

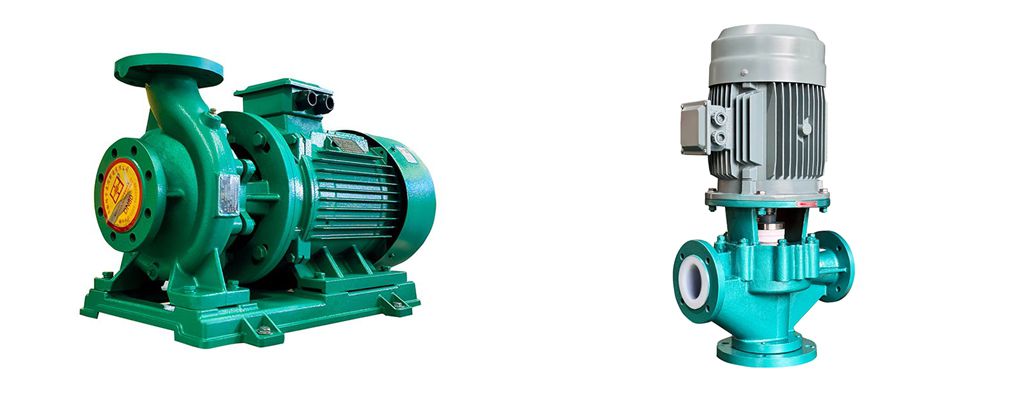

Pumps are classified as horizontal or vertical based on shaft orientation.

Horizontal centrifugal pumps feature a horizontally positioned shaft, facilitating installation and maintenance but occupying more space;

Vertical centrifugal pumps have a vertically arranged shaft, requiring minimal floor space and being suitable for confined areas like well pumping or ship bilge drainage.

V. Classification by Pump Housing Joint Type

Based on housing structure, pumps are categorized as horizontally split or vertically split.

Horizontal split casings divide along the axial centerline for easy internal component access;

Vertical split casings separate vertically, suitable for high-pressure applications with superior sealing integrity.

VI. Classification by Flow Guidance Method

Based on how flow exits the impeller, pumps are categorized as volute pumps or guide vane pumps.

Volute pumps collect and discharge liquid through a spiral-shaped casing, offering simple structure and high efficiency;

Guided-flow pumps direct water flow to the next stage or outlet via guide vanes, commonly used in multistage pumps or high-precision flow control applications.

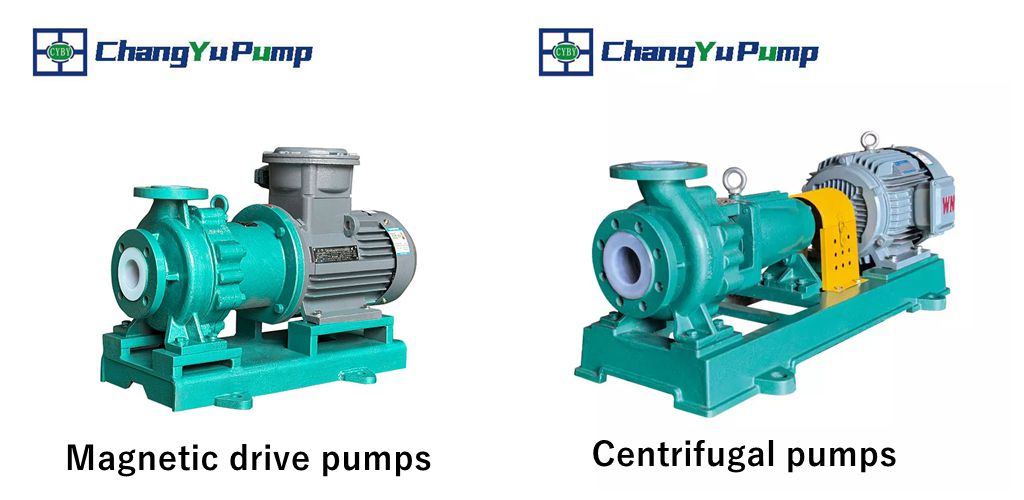

VII. Classification by Conveyed Medium

Centrifugal pumps are categorized by medium type into clean water pumps, oil pumps, corrosion-resistant pumps, etc.

Clean water pumps handle uncontaminated liquid media;

Oil pumps specialize in oil-based media with robust sealing and temperature resistance;

Corrosion-resistant pumps utilize stainless steel, plastic, or similar materials for acids, alkalis, and other corrosive liquids.

How to Select the Right Centrifugal Pump for Your Needs?

After understanding the various types of centrifugal pumps, the most critical step is selecting the correct model based on actual operating conditions and application requirements. Improper selection may lead to inefficiency, increased energy consumption, or even equipment damage. Below are several core selection factors:

Determine medium characteristics (select by conveyed medium): This is the primary step in selection. The properties of the conveyed liquid must be clearly defined, such as:

Water or similar liquids: Standard water pumps may be selected.

Oils, fuels, etc.: Select specialized oil pumps with seals and materials suitable for flammable/explosive media.

Acids, alkalis, salts, and other corrosive liquids: Must use corrosion-resistant pumps (e.g., stainless steel, fluoroplastic materials).

Additionally, consider the medium's viscosity, solid content, temperature, etc.

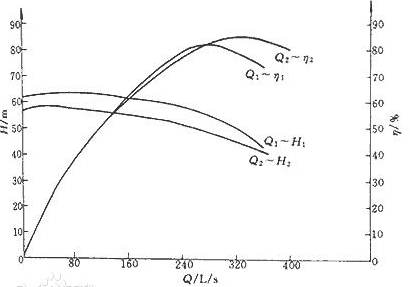

Confirm Flow Rate and Head Requirements (Based on Pressure and Impeller Count):

Flow rate (Q): Volume of liquid to be transported per unit time (m³/h or L/s).

Head (H): Total pressure head the pump must overcome (meters).

Based on calculated required pressure and flow rate, the pump category can be preliminarily determined:

High head, low flow: Multistage pumps may be selected.

High flow, medium-low head: Double-suction pumps may be selected.

Low-pressure, low-flow applications: Single-stage, single-suction pumps may be more economical.

Consider installation environment and space (based on pump shaft orientation):

Horizontal pumps: Facilitate installation and maintenance but occupy larger floor space, suitable for pump rooms with ample room.

Vertical pumps: Require minimal floor space, ideal for confined areas (e.g., deep wells, pits, vessels).

Reference operating conditions and reliability (select by structural type):

For applications requiring frequent maintenance, horizontal split-case pumps allow access without disassembling piping, offering exceptional convenience.

When demanding exceptional operational stability and minimal vibration (e.g., large-scale water supply systems), double-suction pumps are the preferred choice due to their symmetrical inlet design and balanced axial forces.

Selection Process Summary: First analyze the medium characteristics, then calculate the required flow rate and head. Next, consider installation space, budget constraints, and future maintenance convenience. Finally, comprehensively reference the above classification features to determine the most suitable centrifugal pump type.

Conclusion

In summary, centrifugal pumps offer diverse types, each with unique structural features and application scenarios. Proper selection not only impacts system efficiency but directly influences equipment lifespan and operational costs. Should you have any questions regarding centrifugal pump selection, application, or technical details, feel free to consult our professional technical team for free. We provide personalized answers and tailored solutions!

إقرأ المزيد